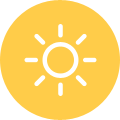

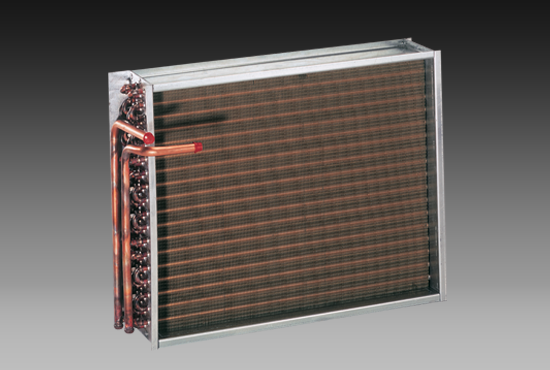

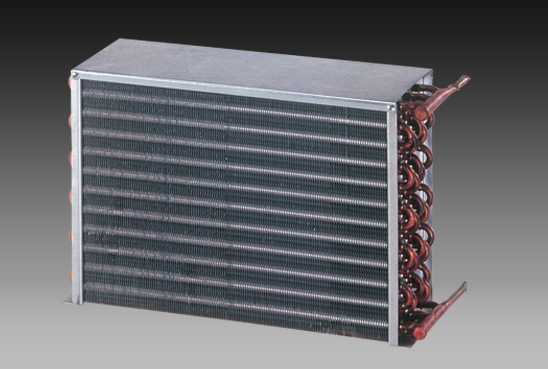

CONDENSERS

Ahmet Yar Sogutma established exchanger production facility in 1984 to meet customer requirements and satisfaction, to develop performance –guarantee products and started serial production. It developed the product range by means of machinery and specialist personnel meeting its requirements.

At exchanger production facility, all evaporators and condensers of different types and models of refrigerated sections and cold room meeting all capacities, evaporators and condensers of shocking and different processes. Materials used in this process respond to all standards by means of high quality.

New hardware and equipment was added to the facility in 2011 and production line was extended and production capacity was increased by different flap moulds, flap figures by means of fully automation controlled system and pipes with different diameters.

Variable pressure tests are carried out in accordance with world standards at exchanger facility. For this reason, our products have any kinds of certificates of quality.