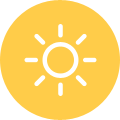

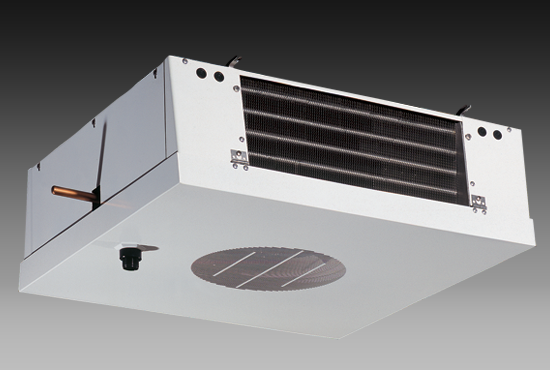

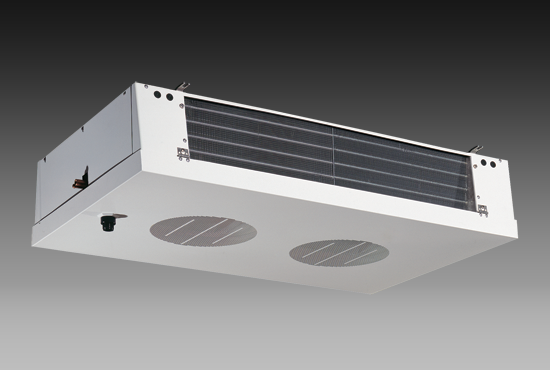

AIR COOLERS

TECHNICAL INFORMATION

- Uses include industrial and commercial food preparation, frozen and shock rooms.

- Two types of applications: Ceiling Type Air Coolers and Wall Type Air Coolers.

- Capacity range from 2 KW to 70 KW.

- Evaporator coil circuits produced according to R-22, R-134 A, R404 A, R407 F refrigerants.

- Low refrigerant charge circuit design.

- Fin spacing of 4,5 -6,5 -7 -8 -11 mm according to application needed.

- Corrugated aluminum fins to increase the efficiency.

- Copper pipes in inlet and outlet connections are suitable for any capacity.

- The refrigerant distributor where the inlet expansion valve is connected ready for use.

- Test pressure of 28 bar.

- Standart application of pressure control valve.

CONSTRUCTION

- Construction of evaporator is 2 mm aluminum the fan casing is made out of 1.2 mm galvanized steel.

- Corrossion protective epoxy coated fins.

- Inside construction is made out of aluminum to prevent rust. Parts are painted with an electrostatic paint system.

- The structure is built according to European Standarts.

FANS

- Air quality is increased by fan connections to venturi type steel.

- Depending on the application the fans can be used as air throw and air draw.

- Fan motor is in protection class IP54.

- Voltage alternatives and pole alternatives for circuit protection.

- Working Temperature range is -40 C / +60 C.

- Electrical protection available in the fans.

- Fan protection according to safety standarts.

DEFROST

- Standart electric defrost.

- Defrost resistance power is suitable for any capacity.

- Alternatives in hot gas defrost.